基于ASME 的轮廓度(带基准)应用和评价

Based on

ASME Y14.5-2009 ASME Y14.5.1M-1994 | ISO 1101-2004 ISO 1101-2012 ISO 1101-2017 | GB/T 1184-2008 GB/T 1184-2018 |

Michael Wu

ASME GDTP-S3990 | 吴超

概要:1. 轮廓度是14个形位公差符号中最为强大的公差符号。

2. 轮廓度可以带基准和不带基准使用。

3. 轮廓度可以控制几何要素的大小、形状、方向和位置。

术语:1. Meas:测量值

2. Outof Tol:超差

3. Max:最大偏差值

4. Min:最小偏差值

结果看Meas,合格看Out of Tol

标准定义:ASMEY14.5.1M-1994 P39-40描述如下:

Actualvalue. For both unilateral and bilateral profile tolerances two actual valuesare necessarily calculated:one for surface variations in the positive directionand one for the negative direction. For each direction,theactual value of profile is the smallest intermediate tolerance to which thesurface conforms. Note that no single actual value may be calculated forcomparison to the tolerance value in the feature control frame,except in the case of unilateral profile tolerances.

轮廓度应用:

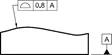

1. BilateralTolerance

2. UnilateralTolerance (inside)

3. UnilateralTolerance (outside)

4. Bilateral Tolerance(unequal distribution

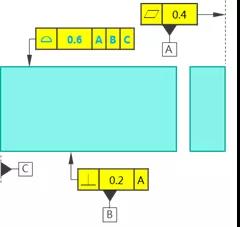

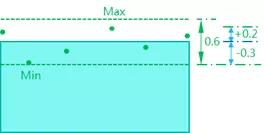

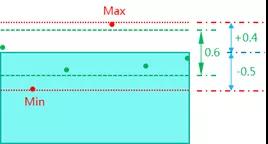

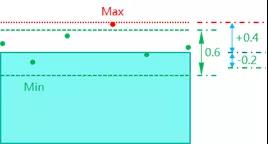

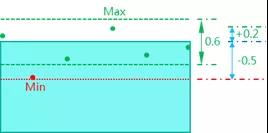

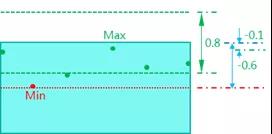

轮廓度评价-1:

带基准:

公差两侧相等:

偏差两侧分布:

定义:

情形如下:

2.

2.

Max=+0.2,Min=-0.3 Max=+0.4,Min=-0.5

Meas=Max-Min=0.5 Meas=Max-Min=0.9

Outof Tol=0 Outof Tol=0.3

3.  4.

4.

Max=+0.4,Min=-0.2 Max=+0.2,Min=-0.5

Meas=Max-Min=0.6 Meas=Max-Min=0.7

Out of Tol=0.1 Out of Tol=-0.2

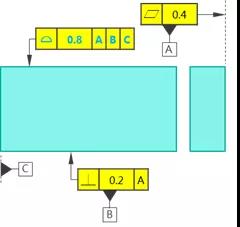

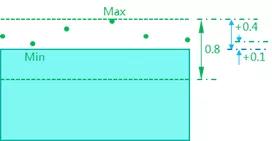

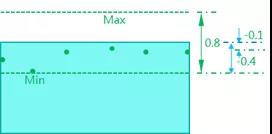

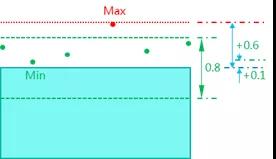

轮廓度评价-2:

带基准:

公差两侧相等:

偏差同侧分布:

定义:

情形如下:

1. 2.

2.

Max=+0.4,Min=+0.1 Max=-0.1,Min=-0.4

Meas=Max-0=0.4 Meas=0-Min=0.4

Out of Tol=0 Out ofTol=0

3. 4.

4.

Max=+0.6,Min=+0.1 Max=-0.1,Min=-0.6

Meas=Max-0=0.6 Meas=0-Min=0.6

Outof Tol=0.2 Out of Tol=-0.2